In the bustling world of global trade, shipping electronics from India to the USA is a task that requires strategic planning and astute understanding of logistics. The cost associated with this journey doesn't just pop out of thin air; it's an amalgamation of numerous elements ranging from transportation modes to international tariffs and regulations.

Businesses looking to explore this corridor need to be savvy about these intricate details to optimize their logistics and budget effectively. Whether it's choosing between air and sea freight or navigating the web of custom duties and taxes, every decision can significantly impact the bottom line.

This article seeks to unravel the complexities of international shipping costs for electronics, offering insights and practical tips to help enterprises achieve cost-effective and efficient outcomes. By understanding the nuances and strategies involved, businesses can forge a smoother path across the oceans.

- Understanding Shipping Costs and Components

- Choosing the Right Shipping Method

- Influential Factors Affecting Shipping Price

- Tips to Reduce Shipping Costs

- Handling Challenges in International Shipping

Understanding Shipping Costs and Components

When venturing into the international shipping realm, deciphering the costs attached to transporting electronics from India to the USA can be more intricate than solving a labyrinth. These shipping costs involve a tapestry of components that businesses must consider to ensure smooth and budget-friendly transits. Initially, transportation modes such as air and sea carry significant weight in determining expenses. Air freight, while speedy, charges a premium that's much steeper compared to the substantial, albeit slower, savings offered by sea freight. Depending on the urgency of the delivery, one might wisely choose the mode that aligns best with their logistical needs.

Diving deeper, the choice of carrier can sway the shipping costs noticeably. Different carriers have varied rate structures, often influenced by their network reach and reliability. For instance, a world-renowned carrier with impeccable service might command higher fees than a regional alternative, leaving businesses to weigh cost against the assurance of delivery performance. One eye-opening aspect to acknowledge is the presence of hidden charges such as fuel surcharges, handling fees, and insurance, which, while minor, collectively build up to a notable sum.

The pivotal elements to consider include the weight and volume of the shipment. Carriers often employ a method called volumetric weight, encouraging shippers to optimize packaging as improperly packaged items can lead to ballooning costs. Import tariffs and customs duties shine a spotlight on political relations between the shipping and receiving countries. These tariffs fluctuate based on policies, meaning businesses should always stay informed to anticipate budgetary changes. Moreover, documentation, often overlooked, plays an essential role in avoiding unnecessary delays and extra charges during customs procedures.

Factors Influencing Shipping Price

Breaking down the various factors that influence the shipping costs unveils a comprehensive picture. First, let's talk about the destination. Shipping to different parts of the USA can incur varying costs due to distance or accessibility. West Coast destinations, for example, might be cheaper compared to East Coast cities, depending on the departure port in India. Seasonal fluctuations are another aspect that shippers must look out for. With the holiday season comes an increased demand for shipping slots, often driving prices up. Planning shipments during off-peak times could lead to better deals.

Incorporating predictability in logistics is key to steering clear of unexpected expenses. According to the International Chamber of Shipping, over 90% of the world’s trade is carried by sea, making it a common choice among shippers. As such, the reliance on accurate data regarding lead times and transit days provides businesses with the foundation to structure their supply chain efficiently. Having a sound understanding of shipping components empowers businesses to transform a daunting logistical challenge into a manageable and systematic trade process.

"Efficient international shipping is more than moving goods; it's about navigating a complex web of economic and regulatory factors." - Caroline Freund, Shipping Economist

Choosing the Right Shipping Method

When it comes to moving electronics from India to the United States, selecting the appropriate shipping method stands as a cornerstone of cost efficiency and timely delivery. It's not merely about opting for the familiar; each shipping method has its intricacies, influencing the shipping costs, speed, and safety of your goods. The two dominant players in this arena are air freight and sea freight, and understanding which best aligns with your business needs is crucial.

For businesses prioritizing speed, air freight shines brightly as the ideal option. While the costs can be on the higher side, the advantage of reduced travel time is an enticing offer, especially for those dealing with high-demand cycles or shifting trends. Air freight tends to be more predictable, with established timetables and fewer disruptions compared to sea routes. For electronics that require expedited delivery, air freight is often indispensable. However, the limited capacity and significant shipping costs sometimes pose limitations.

"Air freight is not just a shipping choice; it's a tool for modern logistics that businesses can leverage to stay competitive," says John Smith, logistics analyst at Supply Chain Weekly.

On the other hand, sea freight is a trusty workhorse for those looking to ship large volumes of products with a focus on cost-efficiency. When time isn't the overriding concern, this method proves significantly more economical, allowing businesses to ship larger quantities at a reduced rate. The complex network of shipping lanes does require careful planning and anticipation of potential delays. A great upside to sea freight is its eco-friendliness, often highlighted for its lower emissions per unit transported. However, companies need to brace for lead times, often ranging from weeks to months, an essential consideration for inventory management.

Several variables play into the decision-making process. Volume and weight are prime considerations; typically, the larger the shipment, the more economically viable sea freight becomes. On top of that, the nature of the electronics being transported is a crucial factor. Fragile components may necessitate air shipment due to reduced handling and lower risk of damage. Seasonal demands can also affect your choice. Peak seasons in either trading country can cause backlogs in shipping lanes or airports, impacting delivery times and costs. So balancing between immediate needs and the broader logistics strategy is key in choosing the right method.

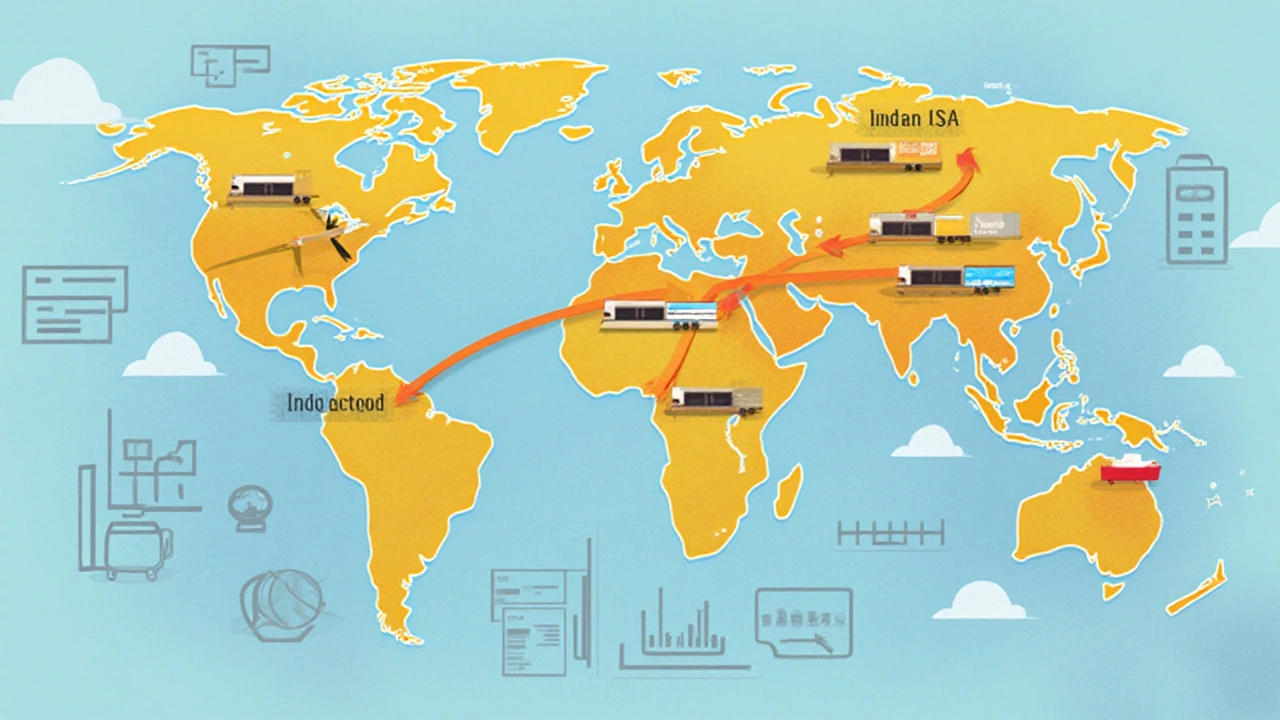

Let's not forget the nuances presented by intermediary choices like logistics companies and carrier services. Collaborating with shipping experts who understand both regional and international logistics intricacies can make a significant difference in cost-saving and protecting your goods. Orchestrating between different shipping legs, whether through train, ship, or airplane, can optimize routes to save time and reduce costs. Often, using a combination of both air and sea—known as a hybrid method—can offer a balanced approach for companies looking to capitalize on the strengths of both modes.

Armed with these insights, enterprises are better prepared to craft a shipping strategy that not only meets their immediate needs but also strengthens their position in the competitive electronics market. Each decision, no matter how nuanced, plays a role in ensuring that products cross oceans efficiently while keeping the budget intact.

Influential Factors Affecting Shipping Price

Shipping costs from India to the USA for electronics aren't determined by a single variable, but are affected by a complex interplay of several factors. Understanding these dynamics can help businesses make informed decisions, potentially saving both time and resources. One of the most significant influences is the weight and volume of the shipment. The size and heaviness directly impact how much space and fuel will be required for transportation. Carriers often use dimensional weight, a pricing technique that considers the physical size of a shipment compared to its actual weight, to determine charges. Therefore, businesses handling large electronics shipments must pay attention to how they pack their goods.

Another critical factor is the mode of transport chosen—air or sea. Air freight is faster but also more expensive, often preferred for high-value or time-sensitive goods. In contrast, shipping by sea is more cost-effective for bulk shipments but can significantly extend delivery times. The choice between these methods should align with the nature of the electronics being shipped and urgency of demand. Businesses should also take into account seasonal variations in shipping rates. During peak seasons like holidays, demand for shipping increases, leading to elevated costs due to limited capacity.

Tariffs and customs duties imposed by both Indian and American governments further complicate the equation. These charges can make a significant dent in the shipping cost of electronics, especially since certain electronic components are subject to higher duties. Understanding these regulations is essential for companies to avoid unexpected expenses. Additionally, some ports of entry might impose unique fees or require extra documentation, adding to the cost. Currency fluctuations between Indian Rupee and US Dollar can also unpredictably affect the final shipping costs. Keeping abreast of exchange rate trends can be beneficial.

"Effective management of the shipping process encompasses keen insights into these nuanced factors," says John Brew, a seasoned logistics expert. "Predicting these influences can vastly improve a company’s operational efficiency and cost management."

Some companies use logistics technology and partners to streamline the shipping process. By employing tracking systems and collaboration platforms, businesses can reduce errors and delays, leading to cost savings. These tech solutions can alert shippers to inefficiencies and allow for proactive adjustments. Partnering with reliable carriers who have established networks and negotiated rates can present opportunities for better pricing. Regular audits of shipping invoices can reveal hidden fees or discrepancies, contributing to more transparent cost management.

| Factor | Influence on Cost |

|---|---|

| Weight and Volume | Directly proportional |

| Transport Mode | Air costlier but quicker; Sea cheaper but slower |

| Customs Duties | Variable based on type of electronics |

| Currency Exchange | Can cause fluctuation in pricing |

| Seasonality | Higher rates during peak seasons |

Tips to Reduce Shipping Costs

Shipping doesn't have to feel like navigating a labyrinth when sending electronics from India to the USA. Costs can quickly spiral if left unchecked, yet reducing these expenses requires a dash of creativity, a pinch of strategy, and a whole lot of know-how. One primary approach is to leverage the economies of scale. By consolidating shipments, businesses can often negotiate better rates with carriers. This practice involves combining multiple small shipments into one large cargo, which is often less expensive per unit. Many shipping companies are more inclined to offer discounts on larger shipments, making it a win-win for both parties involved.

Diversifying shipping methods is another way to trim those pesky costs. While air freight delivers speed, it also brings hefty costs along for the ride. Sea freight, although slower, is considerably cheaper, and businesses can use this to their advantage. For non-urgent goods, booking a sea shipment might be the smart call. Companies should evaluate their inventory, decipher which products need expedited shipping, and balance the shipping methods accordingly. They'd be wise to remember that patience pays off – quite literally in this case.

It's not just about which mode of transportation you choose but also when you choose to ship. Shipping costs have a tendency to fluctuate based on the time of year. By analyzing trends in shipping schedules, businesses can time their shipments to occur during less busy periods. Avoiding high-demand times like around major US holidays can lead to substantial savings. Some shipping wizards even map out annual calendars, identifying peak and valley periods for shipping.

"Shipping costs can be as unpredictable as the weather, but with the right forecast, you can steer clear of any storms," says logistics expert, Mike Brant.

Lastly, it’s crucial to be diligent when it comes to packaging. Electronics are delicate, requiring careful consideration in packaging materials. However, bulky or oversized packaging can lead to inflated costs. Efficient packing, using precisely the amount of material to ensure safety without adding unnecessary size, can keep prices down. Reevaluate packaging techniques regularly, exploring eco-friendly and compact options that minimize both volume and weight.

| Shipping Method | Cost Range (USD) | Estimated Delivery Time |

|---|---|---|

| Air Freight | $2,500 - $4,000 | 3 - 7 days |

| Sea Freight | $700 - $1,200 | 4 - 6 weeks |

Ultimately, staying informed about all the moving parts in shipping logistics is vital. Continuously assess and refine shipping processes, looking for new methods and strategies to keep costs at bay. The quest for economical shipping is ongoing, but with thoughtful planning and strategic action, these tips can pave the way to noticeable savings.

Handling Challenges in International Shipping

In the dynamic milieu of international shipping, especially when moving electronics from India to the USA, challenges are as varied as they are plentiful. Understanding these hurdles is crucial to ensure a smooth logistics operation. For starters, varying international regulations on safety and compliance standards can prove daunting. Each country has its stringent import rules tailored largely around safety protocols and ecological impacts. Businesses must familiarize themselves with these multifaceted layers of requirements, which can be a formidable exercise without the right expertise.

An equal hurdle lies in the inevitability of delays—whether due to weather disruptions or unexpected customs scrutiny, time is of the essence. These hold-ups not only drive up the costs with potential storage charges but also affect the predictability of deliveries. It's a nail-biting reality for businesses that rely on timely delivery windows to maintain customer satisfaction and operation efficiency. To mitigate these, enterprises might consider padded timelines, capable freight forwarding partners, or real-time tracking technologies aiding transparency for every step of the process.

Shipping costs also dance to the tune of currency fluctuations and fuel surcharges, adding another layer of complexity. Sudden changes in exchange rates can skew freight budgets, particularly across major economies with volatile currencies. Consistent tracking of fuel prices and geopolitical developments becomes vital, enabling businesses to anticipate fluctuations and factor them into pricing strategies or explore hedging options. The added peace of mind knowing your budget won't sink under unexpected pressures shouldn't be underestimated.

Another hurdle to steer through is the labyrinth of custom duties and tariffs. With the U.S.'s diverse tariff systems, unexpected costs frequently take businesses by surprise. It's not uncommon for sudden tariff impositions to alter the cost landscape overnight, affecting profit margins and operational budgets. Here, staying updated with trade agreements between both countries and employing customs brokers proficient in regulatory risks could be the lifelines to prevent budget sinkholes.

Insights from Industry Experts

Experts often cite harmonizing efficiency with regulation compliance as the golden rule. Jane Doe, an international trade analyst, once remarked,"Navigating international shipments is like a chess game; anticipate the next move, and you'll always stay ahead of any stumbling blocks."Companies can optimize by regularly training their logistics team, employing technologies that flag regulatory changes or seek partnerships with countries that have favorable trade agreements with the United States.