Ever wondered which factory pushes engineering to the absolute edge? The answer isn’t a single product line-it’s a blend of ultra‑precise steps, massive supply chains, and environments that would make most industries look like kid’s play. Below we break down why complex manufacturing process is a phrase that belongs on the wall of every engineering team.

Defining Complexity in Manufacturing

Complexity isn’t just about how many parts a product has. It’s a mix of three core elements:

- Technical precision: nanometer‑scale tolerances, clean‑room conditions, or high‑temperature metallurgy.

- Process depth: the number of sequential steps, each requiring its own equipment, chemicals, and expertise.

- Supply‑chain interdependence: dozens of sub‑suppliers, each delivering tightly‑spec’d components on a just‑in‑time schedule.

When a single industry scores high on all three, you’ve got a strong candidate for the most complex manufacturing process.

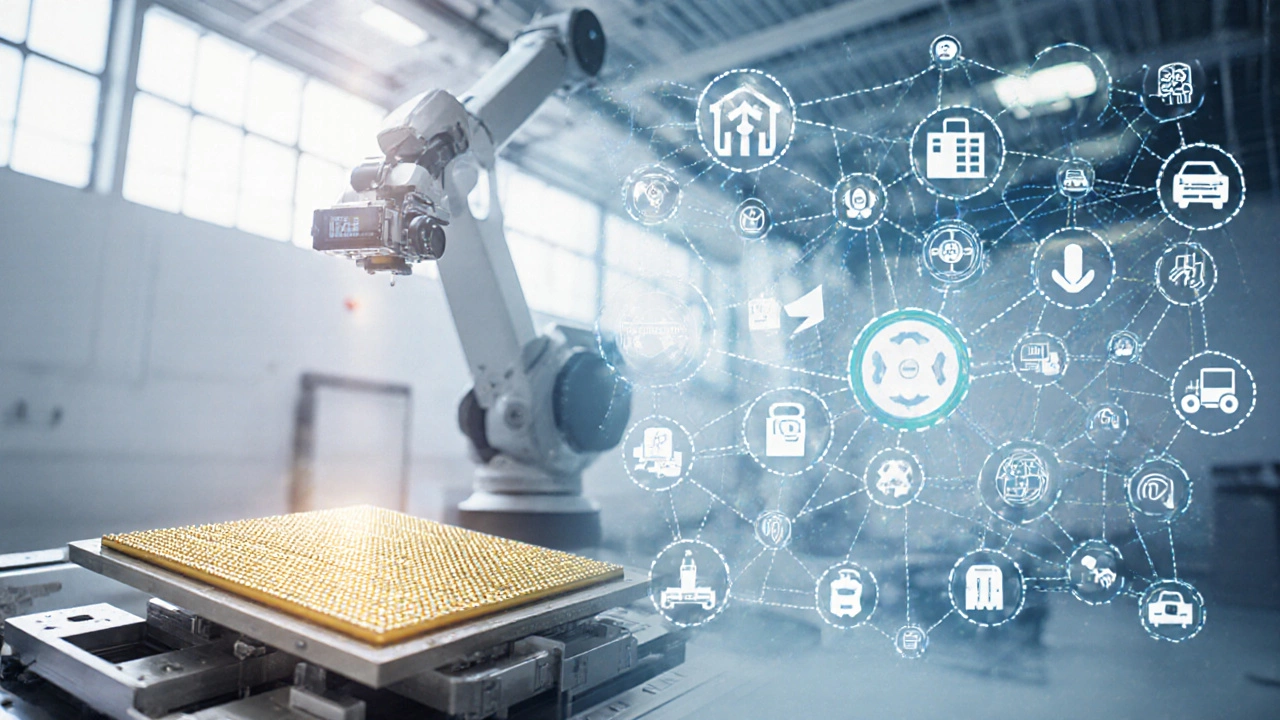

The Champion: Semiconductor Manufacturing (the Fab)

Semiconductor manufacturing is a high‑tech process that turns silicon wafers into micro‑chips used in everything from smartphones to rockets. First introduced in the 1950s, today’s fabs run at sub‑10‑nanometer nodes, meaning a single transistor is only a few atoms wide.

The fab’s complexity stems from a cascade of ultra‑clean, ultra‑precise steps:

- Wafer preparation - slicing an ingot into 300‑mm disks with micron‑level flatness.

- Photolithography - projecting patterns onto the wafer using extreme ultraviolet (EUV) light; each layer requires a new mask, and a modern chip can have 30‑plus layers.

- Etching - chemically removing material where the light didn’t hit, demanding precise gas flows and plasma control.

- Chemical Mechanical Planarization (CMP) - polishing the wafer to a perfectly flat surface before the next layer.

- Doping - implanting atoms to change electrical properties; timing and dosage must be exact.

- Metallization - laying down copper or aluminum interconnects that link billions of transistors.

- Testing - probing each die for defects before it’s packaged.

Every step occurs inside a cleanroom rated at ISO1‑class, meaning fewer than 10 particles larger than 0.1µm per cubic meter. One stray particle can ruin an entire wafer, costing upwards of $10,000 per batch.

Financially, a state‑of‑the‑art fab can cost $15‑$25billion to build, and the recurring expense for ultrapure gases, photo‑resists, and precision tools easily tops $5billion per year.

Close Contenders: Aerospace Assembly

When you think of giant, complex machines, the airplane factory is a familiar image. The Boeing 787 assembly line illustrates why aerospace manufacturing rivals semiconductor fabs in intricacy.

Key complexity drivers:

- Large composite structures that require automated fiber placement (AFP) and curing in massive ovens.

- Systems integration - thousands of subsystems (avionics, hydraulics, fuel, electrical) must communicate flawlessly.

- Regulatory scrutiny - every component undergoes exhaustive certification from bodies like the FAA and EASA.

The 787’s production involves over 50 major suppliers across six continents, each delivering parts with millimeter‑level tolerances. Any delay in a wing rib or engine module ripples through the final assembly line.

Another Heavyweight: Biopharmaceutical Production

The biopharmaceutical production process, especially for monoclonal antibodies and mRNA vaccines, adds a biological twist to manufacturing complexity.

Why it’s tough:

- Living cells are fickle - maintaining optimal temperature, pH, and nutrient levels is a 24/7 job.

- Down‑stream purification involves multiple chromatography steps to isolate the target protein with >99.9% purity.

- Scale‑up from a lab‑scale bioreactor (≈10L) to commercial‑scale (≈2,000L) often introduces unforeseen shear forces that can kill cells.

Regulatory pathways add layers of documentation and batch‑release testing, ensuring that each kilogram of drug meets strict potency and safety standards.

Comparing the Top Three

| Aspect | Semiconductor Fab | Aerospace Assembly | Biopharma Production |

|---|---|---|---|

| Precision Level | Sub‑10nm | Millimeter‑scale composites | Cell‑culture parameters (±1°C, pH ±0.05) |

| Process Steps | 30+ lithography cycles per wafer | ~500assembly operations per aircraft | ~200 purification & formulation steps |

| Supply‑Chain Nodes | ≈200 specialized vendors | ≈50 major suppliers | ≈30 raw‑material and equipment providers |

| Capital Investment | $15‑$25B per fab | $5‑$10B per aircraft model | $0.5‑$1B per facility |

| Cleanroom Requirement | ISO1‑3 | ISO7‑8 (assembly zones) | ISO5‑7 (bioreactors) |

Looking at the table, semiconductor manufacturing tops the chart in raw precision and step count. Aerospace wins on sheer physical scale, while biopharma brings biological variability into the mix. If you ask experts to pick a single “most complex” process, the consensus tilts toward the fab.

Key Challenges That Keep These Processes on Edge

Regardless of industry, a few universal hurdles keep engineers up at night:

- Tool reliability - A single photolithography scanner can cost $120million; downtime ripples through the entire production schedule.

- Human error - Even in ISO‑1 cleanrooms, a mis‑step in chemical handling can scrap a batch.

- Regulatory compliance - New safety standards or export controls can force redesigns mid‑project.

- Data overload - Thousands of sensors generate “big data” streams that need real‑time analytics to catch defects early.

Investing in AI‑driven predictive maintenance, advanced training simulators, and modular equipment designs are the hot ways companies try to tame complexity.

Future Trends: Will Something Even More Complex Emerge?

Quantum‑chip fabrication is already flirting with atomic‑scale tolerances below 1nm. That will push cleanroom standards into the sub‑ISO‑1 realm and demand new materials that don’t outgas.

Space‑manufacturing, like in‑orbit 3‑D printing of satellite components, adds micro‑gravity as a variable. Imagine a process where you must control both vacuum and zero‑g simultaneously.

In biopharma, cell‑free synthesis platforms aim to produce proteins without living cells, merging the precision of chemistry with the flexibility of biology - a hybrid that could rewrite what “complex” means.

When these frontiers mature, the title of “most complex manufacturing process” may shift again, but for now, semiconductor fabs sit comfortably on the throne.

Frequently Asked Questions

Why is semiconductor manufacturing considered the most complex?

It combines nanometer‑scale precision, dozens of tightly linked steps, a massive global supply chain, and ultra‑cleanroom environments. A single defect can ruin an entire wafer worth millions of dollars.

How does aerospace assembly compare in complexity?

Aerospace projects involve massive physical parts, many subsystems, and stringent safety regulations. While the precision isn’t at the nanometer level, the sheer scale and integration of thousands of components make it highly complex.

What makes biopharmaceutical production uniquely challenging?

Living cells are variable, requiring tight control over temperature, pH, and nutrient flow. The downstream purification steps are intricate, and regulatory scrutiny adds layers of documentation and testing.

Can AI help reduce manufacturing complexity?

Yes. AI can predict equipment failures, optimize process parameters in real time, and analyze sensor data to catch defects early, which cuts downtime and improves yield.

What future technology might surpass semiconductor fabs in complexity?

Quantum‑chip production and in‑orbit manufacturing are emerging fields that could push precision and environmental control to new extremes, potentially making them the next contenders for “most complex” title.