Steel Grade Selector

Choose the right steel grade for your project based on application requirements and top producer recommendations

TL;DR When it comes to premium steel, TataSteel, ArcelorMittal, NipponSteel, POSCO, and Thyssenkrupp consistently outperform rivals thanks to advanced metallurgy, strict quality control, and global certifications.

What Makes Steel "High‑Quality"?

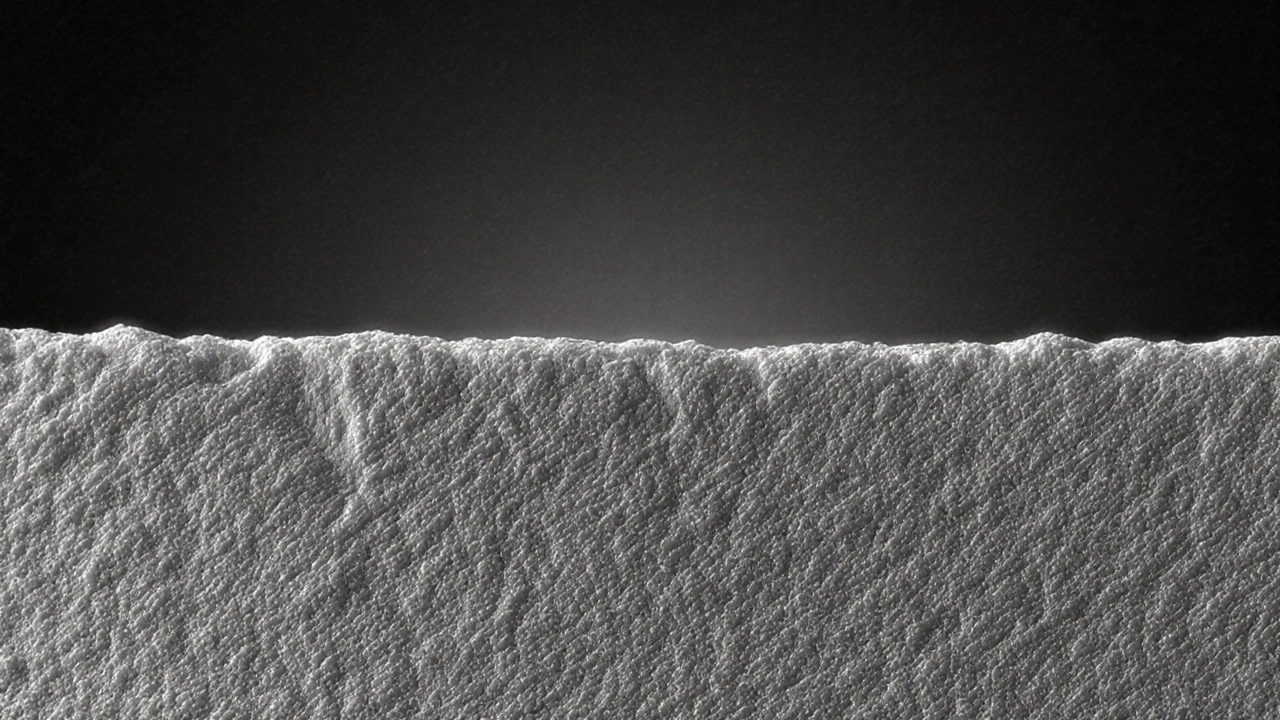

Before naming the leaders, it helps to know the yardsticks that separate average steel from the elite. Quality isn’t just about tensile strength; it’s a blend of chemical consistency, impurity control, micro‑structural uniformity, and performance under extreme conditions.

- Chemical purity: Low levels of sulfur, phosphorus, and nitrogen keep the steel ductile and resistant to cracking.

- Micro‑structure: Uniform grain size and controlled phase distribution (e.g., ferrite‑pearlite balance) deliver predictable mechanical behavior.

- Mechanical properties: High tensile strength, impact toughness, and fatigue resistance are verified through standardized tests such as ASTM A370 and ISO 6892.

- Certification: ISO 9001, ISO 14001, and industry‑specific marks like the Japan Industrial Standards (JIS) or European EN standards demonstrate repeatable quality.

- Traceability: Digital batch tracking and mill test certificates let buyers verify every coil’s origin and processing history.

Manufacturers that excel across these dimensions earn the reputation of supplying "high‑quality steel."

How We Ranked the Producers

Our ranking pulls data from three reliable sources:

- Annual quality audit scores released by the International Steel Quality Association (ISQA) for 2024‑2025.

- Production volume of premium grades (e.g., high‑strength low‑alloy, seamless tubes, aerospace‑grade alloys) reported in company sustainability reports.

- Customer satisfaction surveys from major automotive, aerospace, and construction OEMs.

Each factor received a weight (40% audit score, 35% premium‑grade volume, 25% OEM feedback) and the composite gave us a 0‑10 rating.

Top Steel Makers in 2025

Below are the five companies that consistently hit the upper‑range of the quality rating.

Tata Steel is a multinational steel producer headquartered in Mumbai, India. It is renowned for its "Tata Quality" program, which applies stringent impurity controls and real‑time spectrometric analysis on every melt. ArcelorMittal is the world’s largest steelmaker, based in Luxembourg. Its “Premium Plus” portfolio includes high‑strength automotive sheets (ASTM A568) and ultra‑clean pipe steel (API 5L X80). Nippon Steel operates out of Tokyo, Japan, and leads the market in advanced high‑strength steel (AHSS) for the automotive sector, employing controlled rolling and bainitic transformation. POSCO is a South Korean steel giant headquartered in Pohang. Its "POSCO Grade" line features seamless tubes with a 0.004% sulfur limit, ideal for offshore drilling rigs. Thyssenkrupp is a German engineering and steel conglomerate based in Essen. The company’s high‑purity stainless‑steel grades (1.4501) meet the strict Germanischer Lloyd classification for marine applications.

Comparison Table

| Producer | Headquarters | Flagship Premium Grades | Annual Premium‑Grade Production (Mt) | Quality Rating (out of 10) |

|---|---|---|---|---|

| Tata Steel | India | TataQ‑800, Q‑500 | 5.2 | 9.2 |

| ArcelorMittal | Luxembourg | PremiumPlusA568, X80 | 6.8 | 9.0 |

| Nippon Steel | Japan | AHSS‑U78, JISS55C | 4.7 | 8.9 |

| POSCO | South Korea | POSCOX80, SeamlessTubes | 4.4 | 8.8 |

| Thyssenkrupp | Germany | 1.4501Stainless, 1.7131Alloy | 3.9 | 8.7 |

| U.S. Steel | USA | USSteel‑Q‑480 | 3.2 | 8.3 |

| Nucor | USA | Nucor‑Premium‑750 | 2.8 | 8.1 |

Why These Five Stand Out

Each leader ticks a specific set of boxes that pushes them ahead of the pack.

- Tata Steel invests heavily in vacuum induction melting, which removes residual oxygen and nitrogen. Their on‑site spectroscopy labs give real‑time feedback, keeping impurity levels below 0.001% for most grades.

- ArcelorMittal benefits from a global R&D network that co‑develops alloys with car makers. Their proprietary “Micro‑Alloyed” process yields steel that meets both high strength (up to 1600MPa) and excellent formability.

- Nippon Steel pioneered the use of controlled‑cooling furnaces that produce a fine bainite structure, ideal for crash‑worthy automotive panels.

- POSCO introduced a low‑sulfur continuous casting line that achieves a sulfur content of 0.004%, a key factor for offshore pipe integrity.

- Thyssenkrupp combines advanced stainless‑steel casting with a “Cleanroom” finishing line, ensuring no surface contamination-critical for marine and medical equipment.

Choosing the Right Supplier for Your Project

Not every premium steel is suited to every application. Here’s a quick guide:

- Automotive body panels: Look for AHSS from NipponSteel or ArcelorMittal’s PremiumPlus sheet.

- High‑pressure pipelines: POSCO’s X80 seamless tubes or TataQ‑800 are the go‑to choices.

- Marine structures: Thyssenkrupp’s 1.4501 stainless steel and Germanischer Lloyd‑certified plates ensure corrosion resistance.

- Construction skyscrapers: TataQ‑500 high‑strength rebar offers a good strength‑to‑weight ratio.

- Aerospace components: NipponSteel’s JIS S55C alloy meets tight tolerances for weight and fatigue life.

Always request a mill test certificate (MTC) to verify the exact chemical composition and mechanical properties before placing an order.

Potential Pitfalls and How to Avoid Them

Even top producers can surprise you if you overlook a few details.

- Spec mismatch: A supplier might quote a grade that looks right on paper but differs in heat‑treatment. Verify the heat‑treatment schedule in the MTC.

- Logistics delays: Premium steel often requires temperature‑controlled transport. Ask the supplier about insulated containers or just‑in‑time delivery options.

- Counterfeit certificates: Some distributors falsify MTCs. Choose factories with ISO 9001 and request digital signatures.

- Regulatory compliance: Certain regions (e.g., EU) demand REACH registration for alloying elements. Ensure your chosen supplier can provide the required documentation.

What the Future Holds for High‑Quality Steel

In the next five years, three trends will reshape the premium‑steel landscape.

- Green hydrogen steelmaking: Companies like TataSteel and ArcelorMittal are piloting hydrogen‑based reduction to cut CO₂ emissions. Cleaner production often translates to fewer impurities.

- Digital twin metallurgy: AI‑driven simulations will predict micro‑structure outcomes before a melt is poured, further tightening quality control.

- Advanced recycling: High‑purity scrap loops will allow producers to maintain alloy integrity while reusing material, lowering costs without sacrificing grade.

Keep an eye on these developments-today’s leaders are also the early adopters of tomorrow’s technology.

Frequently Asked Questions

Which steel grade is best for automotive crash safety?

Advanced high‑strength steel (AHSS) such as NipponSteel’s U78 or ArcelorMittal’s PremiumPlusA568 combines high tensile strength (≥1500MPa) with excellent energy absorption, making it ideal for crash zones.

How can I verify that I’m getting truly "high‑quality" steel?

Request a Mill Test Certificate (MTC) that lists chemical composition, mechanical test results, and heat‑treatment details. Cross‑check the MTC against ISO 9001 certification and look for digital signatures from the producer.

Is green‑hydrogen steel actually higher quality?

Hydrogen reduction reduces oxygen and nitrogen pickup during melting, which can lead to cleaner steel. While the primary benefit is environmental, the side‑effect is often a modest boost in purity and consistency.

Can I get premium steel in small quantities?

Many top producers offer "custom melt" services for orders as low as 5‑10tons, especially when you work through an authorized distributor that aggregates demand.

Which company has the most extensive global network for delivery?

ArcelorMittal, with facilities on six continents, provides the widest logistics footprint, enabling rapid delivery to Europe, the Americas, Asia, and Africa.