Ever wondered what really happens behind the scenes when that perfect cup of instant coffee lands in your mug or when your favourite jeans come out looking just right? There’s a lot of science and planning squeezed into every step. Plenty of folks scratch their heads when they hear the phrase “unit process.” It sounds technical and, let’s be honest, a bit intimidating. But here’s the twist: unit processes are all around us, quietly working away in every corner of modern manufacturing. Without these small, well-defined steps, building anything at scale—or even at home—would be pure chaos. To see how it all comes together, let’s dig into what makes up a unit process, walk through some concrete industrial examples, and unpack why knowing about these processes can actually be pretty handy for your own work or business.

Understanding Unit Process: The Nuts and Bolts

A unit process is not some mysterious black box. It’s simply a building block—a single transformative step in a bigger manufacturing workflow. If you’ve ever baked a cake, each action (mixing, baking, frosting) could be seen as a unit process on its own. In industry, these are defined far more strictly. Each unit process involves a chemical or physical transformation, moving raw materials one step closer to a finished product.

The classic definition comes from chemical engineering. Here, a unit process refers to a particular chemical conversion, such as oxidation, hydrogenation, sulfonation, or nitration. It’s the action where something actually changes—not just moving, blending, or heating, but a transformation like turning ethylene into ethylene oxide.

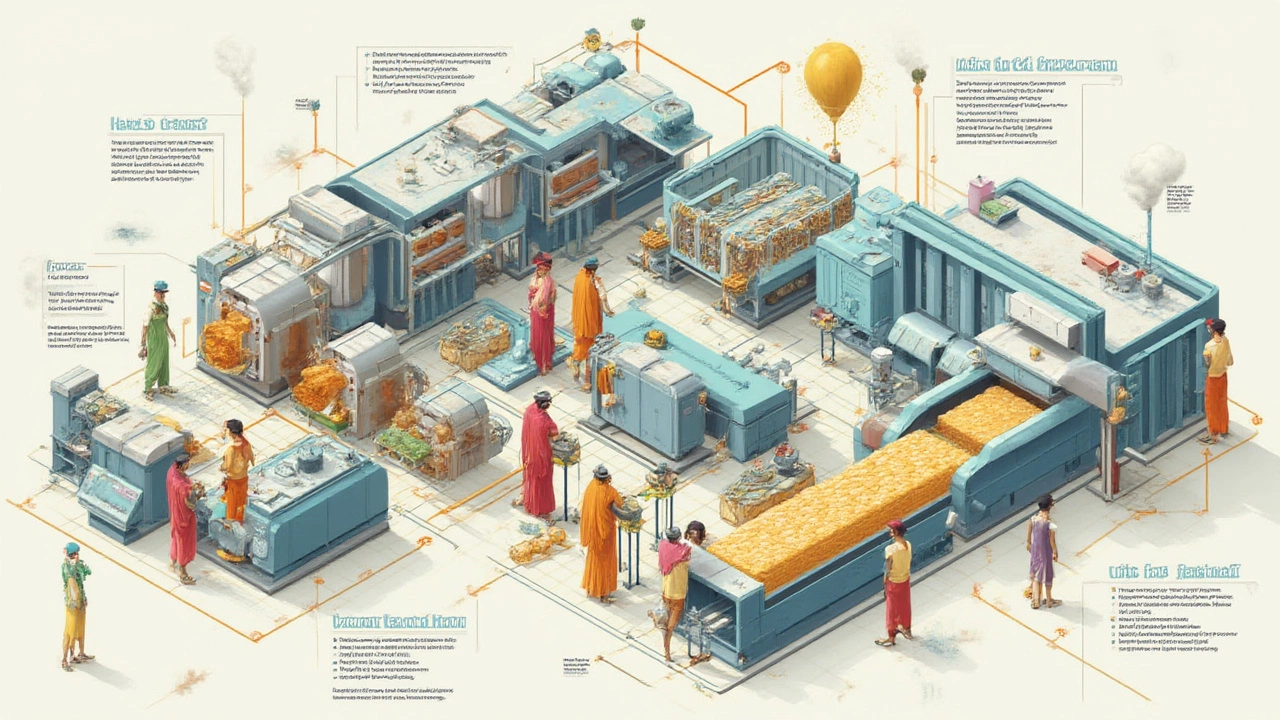

And it’s not just a chemistry thing. Across all manufacturing, from food and textiles to steel and electronics, unit processes shape how factories turn the rough into the ready. In every flow diagram or plan, these steps are mapped out with military precision. Think of a car assembly line: painting the chassis is one unit process, welding body panels is another, fitting the wheels yet another. Divide and conquer is the secret sauce here.

These units are pieced together to form a “process route.” Imagine building a Lego set step-by-step, ensuring everything fits together just right. If one unit messes up, the entire workflow feels the pain. That’s why factories obsess over measuring and optimising each process: downtime or sloppy output at any stage will grind the whole operation to a halt.

The unit process idea popped up in the early 1900s, when chemical plants desperately needed a way to track and improve productivity. Instead of wrestling with gigantic tangled factory diagrams, engineers could focus on tweaking individual units. Over time, the approach began popping up in textiles (dying and finishing), automotive shops, steel plants, and even modern tech factories. By now, unit processes are so popular that there’s almost an international language around them. In training and certifications, “process flow diagrams” and unit process charts are crucial topics.

The real kicker—unit processes aren’t the same as “unit operations.” That’s a common mix-up. Unit operations are physical actions (glorified verbs, really): distilling, drying, crushing, filtering. Unit processes, on the other hand, are when materials actually change chemically. It’s a small shift in focus, but in the world of manufacturing, it makes all the difference.

One study in the Journal of Cleaner Production (2022) showed that mapping out unit processes on factory lines allowed operators to cut waste by 12% on average. That’s real money and less pollution too. No wonder businesses chase these “invisible steps of value” so closely.

Ever seen process improvement kaizen posters in workplaces, or those stickers that show “Step 7: Apply Sealant”? That’s all about nudging each unit process toward more consistent gains. And it’s not just for factory geeks—startups and scale-ups track these steps to understand costs, control quality, and spot bottlenecks before they become huge headaches.

Real-World Examples of Unit Processes in Manufacturing

Alright, enough theory. Let’s get our hands dirty with some real examples of unit processes that you’ll find in ordinary products, whether you realise it or not.

Take textile manufacturing—a surprisingly complex industry. Making jeans out of cotton isn’t just a single process. Textile plants break the whole thing down into a series of unit processes: spinning, dyeing, washing, and finishing. The dyeing process, for example, is a classic unit process where raw fabrics are chemically treated to bond colour molecules. Miss a step, or use the wrong temperature, and your blue jeans end up streaky or faded long before their time.

Chemical manufacturing gives us some textbook cases. In pharmaceuticals, synthesising an antibiotic might go through several unit processes: nitration to introduce a nitro group, reduction to turn nitro into amino, and acylation to add side-chains. Each of these is a chemical event, often performed in separate reactors with precise controls. Below is a simple table showing typical unit processes in making paracetamol (acetaminophen):

| Step | Unit Process | Description |

|---|---|---|

| 1 | Nitration | Conversion of phenol to nitrophenol by adding a nitro group |

| 2 | Reduction | Nitrophenol is reduced to aminophenol |

| 3 | Acetylation | Aminophenol is acetylated to form paracetamol |

Food processing plants rely on unit processes, too. Making instant coffee? The coffee beans are roasted (another unit process), then ground, brewed, concentrated by evaporation, and finally spray-dried into powder. Each stage transforms the material in a specific way—roasting browns and flavours the beans, brewing extracts soluble compounds, and so on. Even spraying the coffee to make powder is an engineered unit operation where new chemical bonds form with water molecules.

Car manufacturing lines are textbook examples of unit process management in action. Let's say you're building a classic car in Birmingham (like the old Mini). You'd start with stamping—the sheet metal is pressed into shape. That’s a unit operation since it’s physical, not chemical. Next comes phosphating, a chemical process where a layer forms on the car body to resist rust. That’s our unit process. Painting, too, involves chemical changes as paint cures and hardens. Engine assembly? Fuel injectors are fitted and tested at carefully planned stations. The beauty is in how these bits are lined up: each one changes the product, moves it closer to finished, and leaves a visible difference.

Electronics, meanwhile, take things up a notch. Making a silicon chip boils down to unit processes like doping (adding impurities to tweak electrical properties), photolithography (using light to create microscopic patterns), and etching (removing bits of silicon to craft circuits). Less margin for error here: the difference between a perfect chip and a dud might be measured in atoms.

Even on the shop floor, individual unit processes get tracked through digital sensors, IoT devices, and dashboards. If you walk through a modern food plant, you’ll see laser sensors checking product flow during each unit step. Missed targets or weird timings trigger instant alerts. Some places even use AI to suggest tweaks, further fine-tuning how those unit steps add value.

Want another number? Unilever, one of the world’s biggest consumer goods companies, reported in 2023 that applying unit process analysis to its soap production cut defects by 15% at one UK site. Massive savings in money, materials, and reputation.

If you’re trying to boost your own workshop, don’t ignore these invisible steps. You can break almost any routine down into unit processes: prepping surfaces, mixing ingredients, assembling, checking finish. The more you know which step does what, the easier it is to spot weak links, tweak quality, and cut costs.

Tips for Applying Unit Process Thinking Beyond the Factory

Let’s get practical: you don’t need a factory or PhD to make unit process thinking work for you. There’s plenty to learn from manufacturers about streamlining tasks, reducing errors, and boosting results just by breaking things down.

First up, start mapping your work routines or business steps as a series of transformations. For example, if you run a small bakery in Birmingham, maybe with dreams of going big, your daily bread-making routine can be plotted out: weighing (unit operation), mixing (unit operation), fermenting (unit process—chemical change), baking (another process, since dough changes permanently here), and packaging. If your loaves keep coming out wonky, zero in on the “fermenting” process—track temperature, times, and ingredient ratios more closely.

In services, unit process thinking isn’t as common, but it still helps. Say you manage an IT support team. You move from diagnosis (unit operation, sorting issues), to patching a system (unit process, since you permanently change the codebase), and then to customer follow-up. At every transformation point, try to nail down exactly what changes, who’s responsible, and how you know it worked. Document the flow and spot speed bumps or sources of mistakes quickly.

Here’s a tip: Use simple flow charts or sticky notes to lay out your steps and identify where actual changes (processes) happen, versus just physical moves or checks (operations). This makes it much easier to track outcomes and measure improvement over time.

For those in startups, investors love teams who think in unit processes. It spells out that you know how your secret sauce gets made, enabling easier scaling and better costings. That’s especially handy when making pitches to backers or hiring new staff—nobody wants to be in the dark about which bits matter most.

If you’re in charge of sustainability and reducing waste, looking at processes this way will help too. A 2022 analysis in The Manufacturer magazine found that smarter unit process controls slashed water use in a Midlands textile plant by 20%, just by tweaking dye-bath timing and tracking discharge valves. That’s cash saved and eco-credentials polished.

Another practical angle: measure what matters at each step. Labelling each process makes it simple to set up quality checks, sensors, or even quick “go/no-go” controls, just like the big industry names do. And don’t be afraid to ask workers or teammates—those on the front lines have the best knowledge of where things get stuck, so listen when they flag a specific process for a closer look.

For the numbers-minded, here’s a tip: break down costs by unit process. This gives a crystal-clear look at where money’s going, helping find savings. It’s a tool the big boys use for budget reviews and investment decisions.

Here’s the real kicker—every improvement in a single unit process adds up across the bigger whole. A 2% bump in one step can snowball into huge payback when multiplied across a full batch or annual run. Instead of chasing vague targets like “run faster” or “save money,” zooming in on each transformative step will actually get you there—with far less waste and stress.

Mastering the art of unit process thinking means you’re treating your work like a pro manufacturer: always tweaking, always improving, always learning. Whether it’s jeans, bread, code—or something only you can imagine—understand those defining steps, watch how they change your end result, and you’ll have a huge edge in any field.