Global Supply Chain

When navigating global supply chain, the worldwide network that moves raw materials, components, and finished goods across borders. Also known as international supply network, it connects manufacturers, logistics providers, and retailers to deliver products to end‑users. This network touches almost every industry you can think of – from steel plants in Pittsburgh to textile mills in India. Understanding how the pieces fit together helps you spot risks, seize opportunities, and make smarter decisions today.

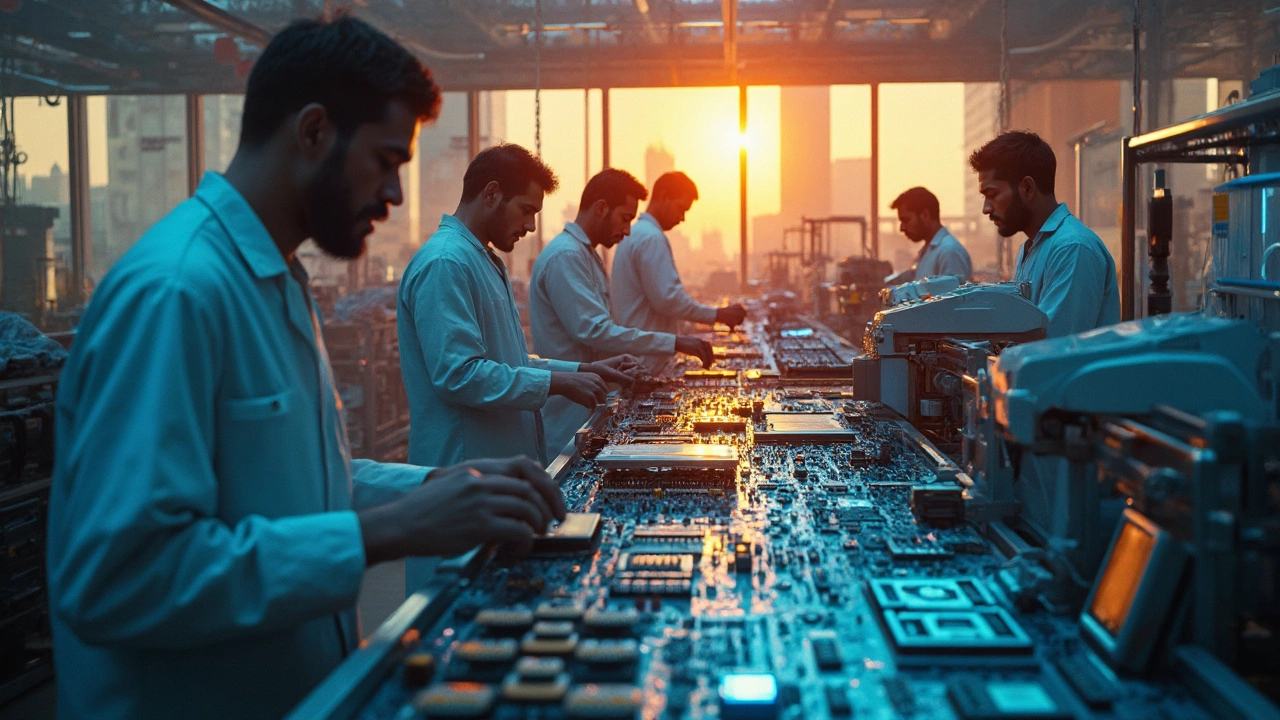

global supply chain isn’t a single thing; it’s a set of interlocking processes. One of the core pieces is manufacturing, the stage where raw inputs become finished products. Manufacturers decide where to locate factories, what technologies to adopt, and how to balance cost with quality. In India, firms like Arvind Limited dominate textiles, while Pittsburgh’s steel legacy shows how regional expertise can shape global flows. Because manufacturing creates the physical goods, it directly defines the volume and type of items that later move through the network.

The next link is logistics, the planning and execution of transporting goods by road, rail, sea, or air. Logistics determines speed, cost, and reliability of delivery. A well‑designed logistics network can shave days off lead times, cut freight expenses, and reduce carbon footprints. For example, the US plastic hubs in Texas and California show how geography and infrastructure shape where factories cluster and how products flow to markets. Logistics enables the movement generated by manufacturing.

Once goods are in transit, inventory management, the practice of balancing stock levels with demand forecasts, becomes critical. Companies keep safety stock to guard against delays, but too much inventory ties up cash. The rise of just‑in‑time (JIT) strategies illustrates how tighter inventory can boost efficiency, yet also increase vulnerability to disruptions. Effective inventory management requires accurate data from both manufacturing output and logistics performance.

All of these steps run under the umbrella of trade compliance, the set of rules, tariffs, and regulations governing cross‑border movement. Customs duties, export controls, and regional trade agreements can add cost or create bottlenecks. Recent changes in US‑China trade policy, for instance, forced many plastic manufacturers to rethink sourcing and routing. Trade compliance influences every decision upstream and downstream in the supply chain.

Because each component—manufacturing, logistics, inventory, compliance—is linked, the whole system needs resilience. Companies are investing in digital twins, AI‑driven demand forecasting, and diversified supplier bases to absorb shocks. The goal is a supply chain that can keep moving even when a pandemic hits or a port closes. Resilience isn’t a buzzword; it’s a practical set of actions that combine the entities discussed above.

Below you’ll find a curated set of articles that dive deeper into these topics. From the steel legacy of Pittsburgh to the booming plastic hubs in the US, from India’s textile giants to the evolution of AI chips, each piece shows how the global supply chain shapes and is shaped by industry trends. Whether you’re a factory manager, a logistics planner, or just curious about how your favorite products travel, the collection offers concrete data, real‑world examples, and actionable tips.

Ready to explore the details? Scroll down to discover the full range of insights that break down each element of the supply chain and show you how to stay ahead in a fast‑changing world.