Manufacturing Hub: What It Is and Why It Matters

When talking about Manufacturing Hub, a geographic area where factories, suppliers, logistics providers and related services co‑locate to boost industrial output. Also known as industrial hub, it becomes the engine that powers regional economies. These hubs often rely on Mass Production, the large‑scale, standardized method that drives volume while cutting unit costs, and on Small Scale Industry, a network of micro‑factories and craft workshops that serve niche markets and add flexibility. Effective Supply Chain Management, the coordination of raw materials, production schedules and distribution channels is the backbone that keeps the hub running smoothly, while the broader Industrial Cluster, a grouping of related businesses, research institutions and support services in a defined region creates the ecosystem for innovation and talent sharing. In short, a manufacturing hub encompasses industrial clusters, requires robust supply chain management, and is shaped by both mass production and small‑scale industry.

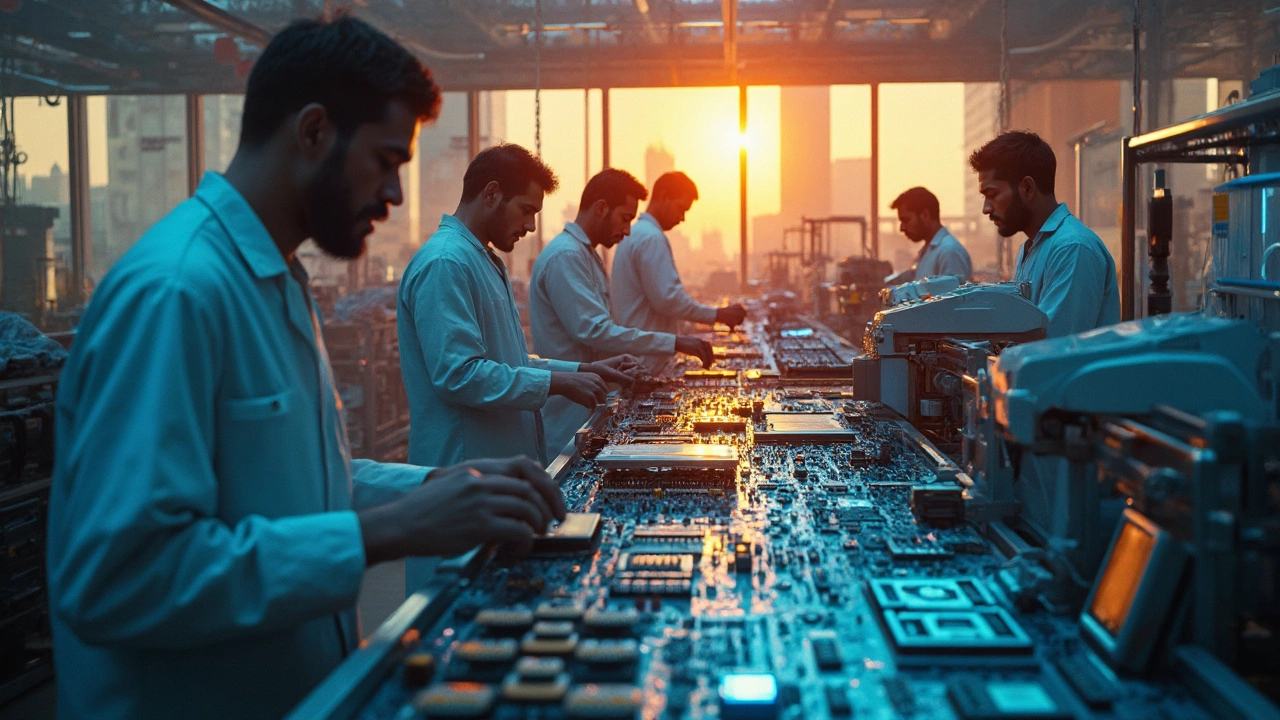

Why Manufacturing Hubs Are the Pulse of Modern Industry

India’s rise as a manufacturing powerhouse is anchored in several well‑known hubs – think of the steel legacy of Pittsburgh in the US, the plastic corridors of Texas and California, or the textile giants like Arvind Limited that dominate the Indian market. Each example shows how a hub can specialize: heavy‑equipment giants such as Caterpillar and Komatsu find strength in regions with deep engineering talent, while AI chip startups cluster around cities with strong semiconductor research. When you add the surge of high‑demand products for 2025 – from ergonomic office furniture to sustainable textiles – you see hub locations adapting quickly, leveraging local supply chains to meet global demand. Small‑scale manufacturing ideas, like the 50+ low‑investment setups highlighted in recent guides, often sprout around larger hubs, feeding niche markets and creating job opportunities without massive capital. The interplay between mass production efficiency and agile small‑scale operations makes hubs resilient against disruptions, whether it’s a raw‑material shortage or a shift in consumer taste. This dynamic is why anyone looking to launch a manufacturing business, explore profitable factories, or understand sector‑specific consumption (like the plastics used by the automotive industry) should first ask: which hub offers the right mix of infrastructure, talent and market access?

Below you’ll find a curated collection of articles that dive deeper into each of these angles – from the mechanics of unit processes to the latest trends in AI chip manufacturing in India. Use them as a roadmap to understand how manufacturing hubs shape strategy, where new opportunities are emerging, and what tools you need to succeed in today’s fast‑moving industrial landscape.