Technology Production: Trends, Tools and Real‑World Insights

When talking about technology production, the process of turning ideas, raw materials and digital tools into finished goods at scale. Also known as tech production, it sits at the heart of modern industry. Manufacturing, the organized creation of products using labor, machines and processes provides the backbone, while industrial automation, the use of robotics, sensors and software to streamline production accelerates output and cuts waste. Even small scale industry, low‑investment manufacturing that serves niche markets relies on these same principles, just on a tighter budget.

Why technology production matters across every sector

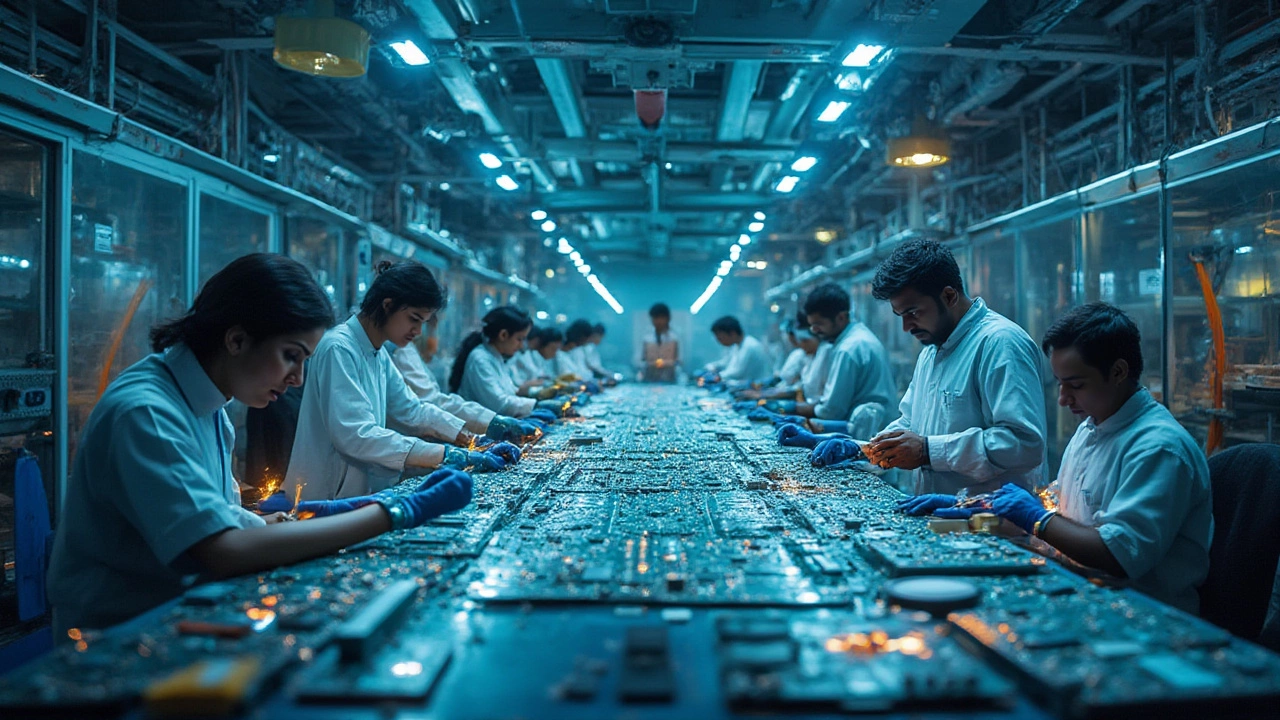

From the massive excavators made by Caterpillar and Komatsu to the next‑gen AI chips being assembled in Indian fabs, technology production is the common thread that ties big‑ticket equipment, consumer gadgets and everyday plastics together. High‑demand products in 2025—think ergonomic office furniture, sustainable home décor and viral snack‑packaging innovations—are all born from a mix of advanced machinery and data‑driven design. That same mix drives the steel legacy of Pittsburgh, the textile supremacy of Arvind Limited, and the booming plastic hubs in Texas and California. Each case shows how adopting newer automation tools, tighter supply‑chain coordination, and smart unit processes can turn raw material into market‑winning goods.

What’s striking is the ripple effect: when a factory upgrades its unit process—say, by adding a precise casting step for plastic components—it not only lifts its own profit margins but also reshapes the demand curve for downstream products like furniture or automotive parts. The "most profitable factories" often combine mass‑production efficiency with niche‑specific tweaks, such as low‑cost micro‑factories for specialty food items or high‑tech labs churning out AI chips. This blend of scale and specialization is the sweet spot for entrepreneurs looking to launch a manufacturing venture with zero experience or no upfront capital.

In practice, the roadmap looks simple: identify a market need, choose the right production technology, and layer automation to keep costs down. Whether you’re scouting the top trending products, calculating which US state ships the most plastic, or figuring out the best material for a new furniture line, the underlying principle stays the same—technology production turns data into dollars. Below you’ll find curated articles that break down each of these angles, from heavy‑equipment comparisons to small‑scale manufacturing ideas, giving you concrete steps to apply these concepts right away.

Ready to dive deeper? The collection that follows unpacks specific sectors, tools and case studies, so you can see how technology production shapes everything from AI chip design in India to the rise of fully Made‑in‑India cars. Explore the posts to sharpen your strategy and spot the next growth opportunity.